ROEDERS

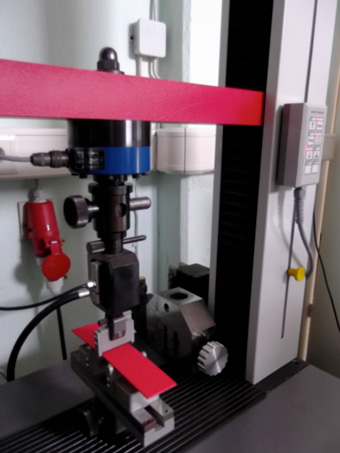

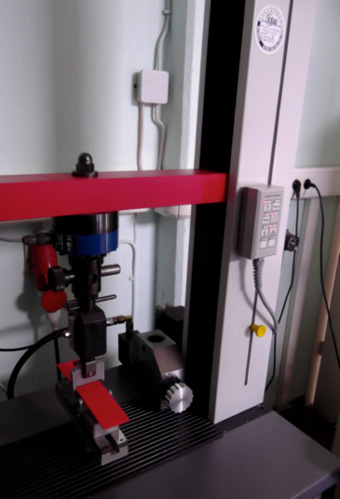

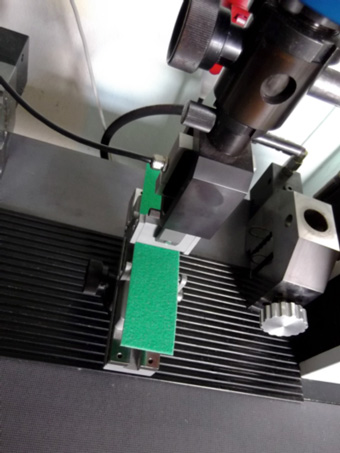

Research/Development.Research and development.

In our own laboratory to new solutions

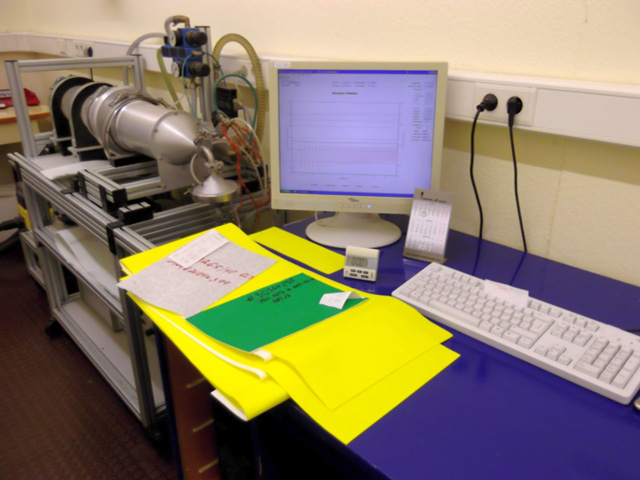

We develop new felt materials and textile products from wool and synthetic fibers. In addition to our own developments, we work on behalf of customers, research new textile applications, and improve existing products and processes with the help of our textile materials.

We are certified, test and work in compliance with standards and beyond.

Our goal is new, intelligent textile applications and products that reduce the burden on the environment, save energy, and effectively and optimally support work and production processes.

Challenge us – we look forward to your inquiry!

Current developments

.

SOLTA®FELT - Classic wool felts dyed, mottled

Wool felt HR-T, OF, OF-T 5.0 mm 0.30 meets the requirement for fire class: B-s2, d0 according to EN 13501-1+A1:2010

SOLTA®TEC - Technical needle felts

Welltex, Toptex – New, high-performance qualities for textile car washing have successfully passed the practical test. Use in car washes and gantry systems.

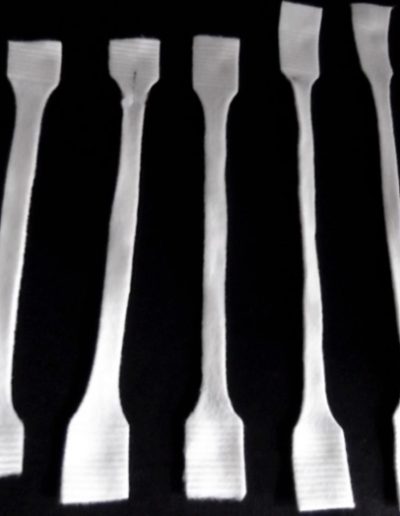

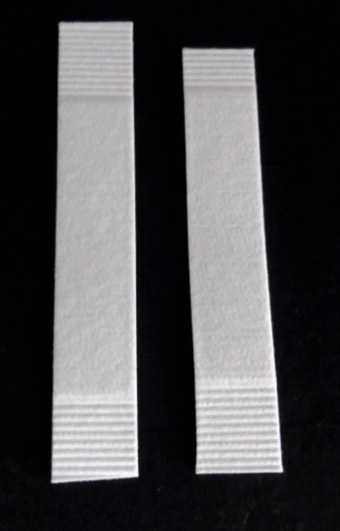

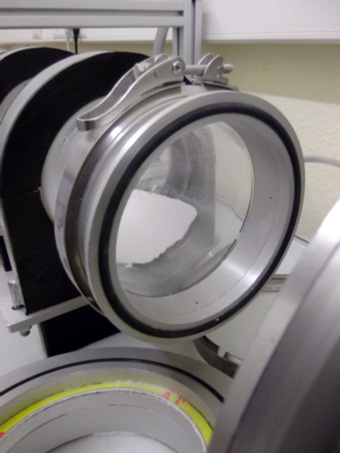

SOLTA®LINER

- Flexible inversion glass liner, single and multilayer compatible with commercially available UP and EP resins. Suitable for use in the DN range from 150 to 1500. Curing with steam or water. Eo in the range of 8000-10000 MPa.

- House connection liner HD – Flexible, bendable liner also suitable for applications with 2 DN transitions. Compatible with most EP resins. Well-suited for steam and water curing methods.

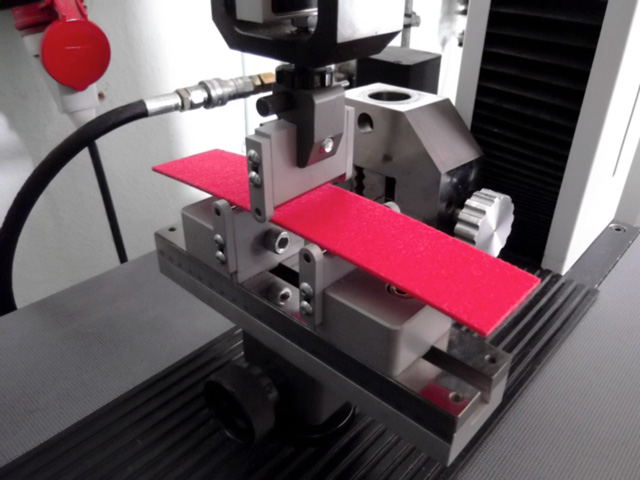

SOLTA®FILT

Further development, specialization of proven dust and belt filters for niche applications.